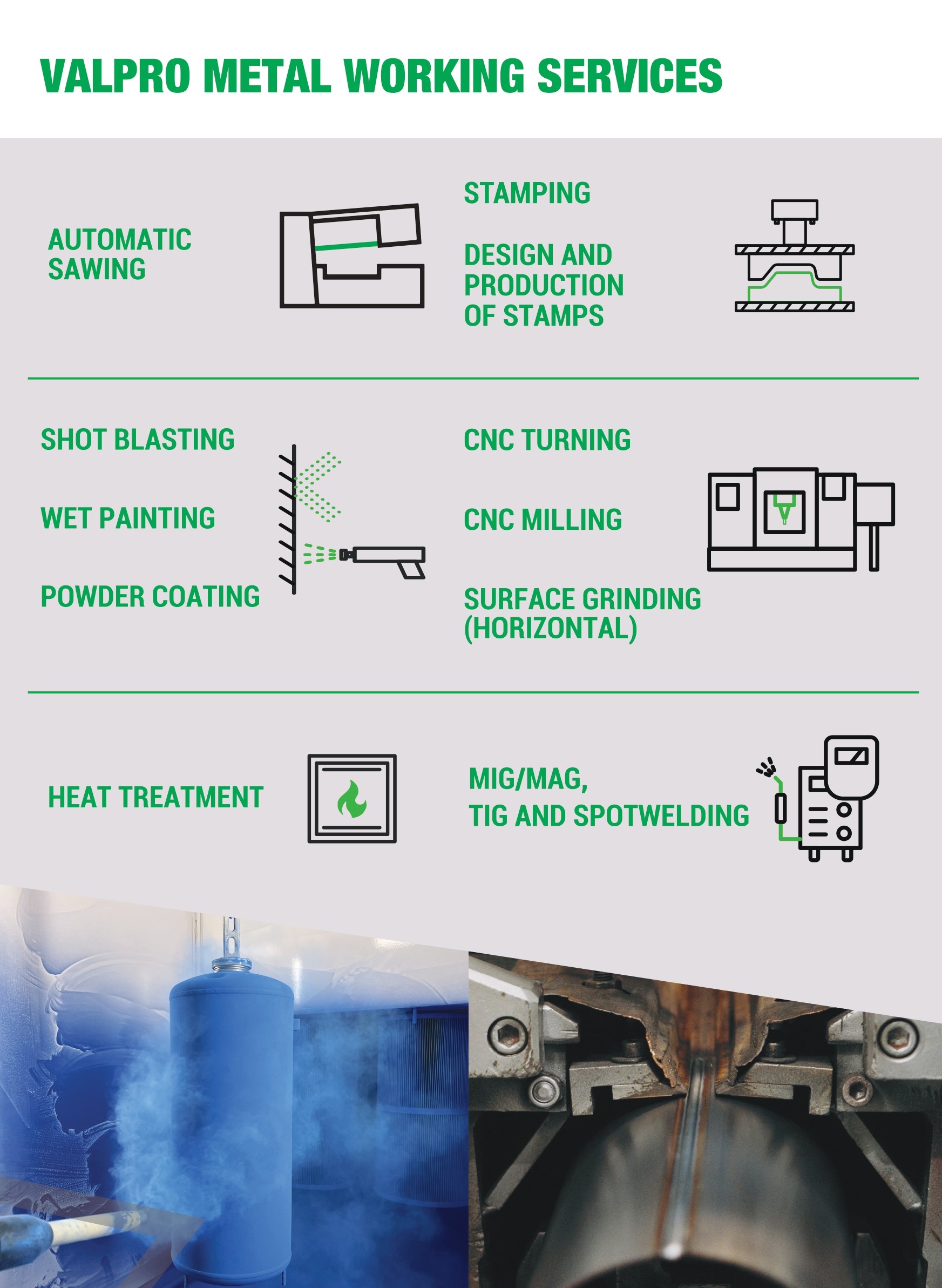

METAL WORKING SERVICES

With over 60 years of experience, VALPRO stands as one of the Baltic region’s leading metalworking companies. At VALPRO, we have built a solid foundation in the metalworking industry, continuously expanding our capabilities and deepening the expertise of our specialists. This commitment allows us to deliver the highest quality services to our clients and provide a complete product cycle - from the creation of blanks to the finished product assembly.

We are proud to offer specialized metalworking services that are rare in Latvia. One such service is deep drawing, a highly efficient metal-forming process that transforms flat metal sheets into products with complex shapes. In addition, we provide automated cutting of metal sheets and parts from coils, ensuring precision and efficiency. Our electric discharge machining (EDM) technology is ideal for producing intricate and precise components, meeting the highest standards of quality.

At VALPRO, we value long-term partnerships and are dedicated to producing high-quality metal parts and assembling them into finished products. Whether you need custom manufacturing, innovative solutions, or reliable service, VALPRO is here to deliver excellence every step of the way.

Download our metal working services cataloge 2024 here

DEEP DRAWINGHighly efficient metal-forming process that transforms flat sheets of metal into hollow objects. This technique is widely used in industries where strength, precision, and cost-effectiveness are critical, making it ideal for producing a variety of components, from automotive parts to household appliances. Technical specifications:

Deep drawing is an essential metal-forming process that combines precision, efficiency and sustainability, making it a preferred choice for manufacturers looking to produce high-quality components at scale. |

|

|

|

METAL SHEET CUTTING FROM COILCrucial process that transforms large coils of continuous sheet metal into flat sheets of specific dimensions. This method ensures high-quality, customizable metal sheets for diverse applications. The process typically involves uncoiling the metal, straightening it and then cutting or punching it into individual sheets or parts of the desired length and form. Technical specifications:

Metal sheet cutting from coil lines offers a blend of precision, efficiency and adaptability, making it an essential process for producing high-quality metal products at scale. |

WIRE EROSION CUTTING (EDM)Wire erosion cutting EDM (Electrical Discharge Machining) is ideal for intricate designs, complex geometries and components requiring precise angles unattainable by conventional methods. Technical specifications:

|

|

|

|

DIE SINKING (EDM)Die sinking EDM (Electrical Discharge Machining), also known as spark eroding, offers an innovative approach to shaping materials using electrical sparks instead of traditional cutting tools. This advanced technique excels in producing highly precise shapes and intricate contours in various conductive metals, making it the go-to solution for complex and demanding machining tasks. Technical specifications:

|

%20(1).jpg)